Competitive advantages

Kotech Oil-Free Air Suspension Turbo Blowers have the following application advantages over similar types of machines.

🔧 Energy efficiency

30–50% lower energy consumption vs. traditional roots blowers.

🛠️ Maintenance

No lubricants/mechanical contacts, annual maintenance cost reduced by 92%.

🚀 Reliability

Semi-permanent design life (>20 years).

📦 Space saving

Compact integrated structure, 50% footprint reduction.

🔇 Eco-friendliness

Zero oil pollution, noise≤80 dB.

Applications

In addition, the blower is also widely used in various complex industries, all aspects of production to meet the needs of enterprises.

- Environmental: Wastewater aeration (30–50% energy savings), desulfurization oxidation.

- Industrial manufacturing: Oil-free air supply for food/pharmaceutical processing, pneumatic conveying in petrochemicals.

- Energy & materials: Cement kiln combustion air, fly ash handling in power plants.

- Special processes: Vacuum packaging, solvent recovery, gas-phase separation.

Core technologies

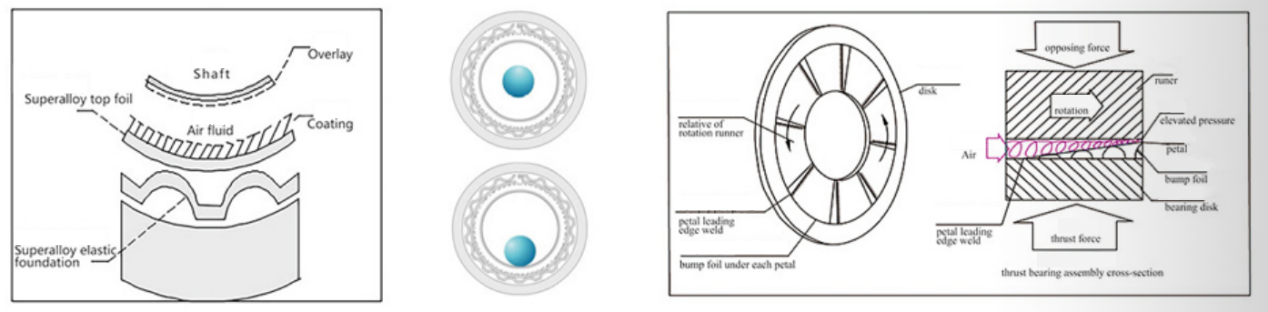

Air suspension bearing system

- Utilizes a hybrid aerostatic-aerodynamic principle: At startup, the rotor contacts elastic foil surfaces (coated with solid lubricant). Upon reaching the lift-off speed (≥20,000 rpm), a high-pressure air film (5–10μm thickness) is formed between the rotor and foils, enabling frictionless levitation.

- Self-regulating throttlers dynamically adjust air film pressure to maintain rigidity under load fluctuations.

- Eliminates lubricating oil, complying with ISO 8573-1 Class 0 oil-free standards.

High-speed permanent magnet synchronous motor

Aerospace-grade impeller

Intelligent control system

Parameters List

| Parameter | Specification range |

|---|---|

| Power range | 15 – 400 kW |

| Operating pressure | 30 – 120 kPa (customizable up to 8,000 mmAq) |

| Flow rate | 6 – 275 m³/min |

| Noise level | ≤ 80 dB (@1.5 m) |

| Rotational speed | 20,000 – 65,000 rpm |

| Certifications | ISO 8573-1 Class 0 oil-free certification Impeller performance certified per AMCA 210 |