Application of Dry Oil-Free Air Compressors in the Chemical Industry

Air compressors provide the necessary compressed air power for chemical product production in the chemical industry, mainly supplying the required pressure for chemical reactions, emission control, and storage. Due to the special nature of chemical materials, the chemical industry has high requirements for compressed air, demanding safe, stable operation and easy maintenance.

The chemical industry requires such air compressors:

Safe and reliable instrument purging: Compressed air is used for purging control panels, production equipment, and production platforms. Even trace amounts of oil can create a flammable environment, so the oil content in the air must be extremely low.

Pure oil-free product production: Even trace amounts of oil can lead to product contamination, equipment failure, and production interruption risks.

Low failure and maintenance costs: The operational drives and controllers of chemical industry production equipment rely on compressed air for normal operation. Oil in compressed air can clog key operating components, increasing the risk of failure.

Temperature-appropriate liquefaction refrigeration: Filtered, temperature-appropriate compressed air, when compressed, cooled, and expanded, can be liquefied for artificial refrigeration.

Gas separation with standard purity: Liquefied gases can be separated to obtain gases of standard purity.

Pressure-ready substance synthesis: Certain gases, when compressed by the compressor to increase pressure, can be synthesized and polymerized under chemical reagents.

Sufficient flow for conveying and filling: Compressed air can be used for the filling and transportation of chemical products.

Stable and reliable process manufacturing: Refining oils, using compressors to pressurize and heat hydrogen, splitting and recombining hydrocarbons in crude oil to produce lighter hydrocarbons. Processes such as desulfurization, catalyst regeneration, process heaters, acid oxidation, and gas-oil desulfurization all require compressed air.

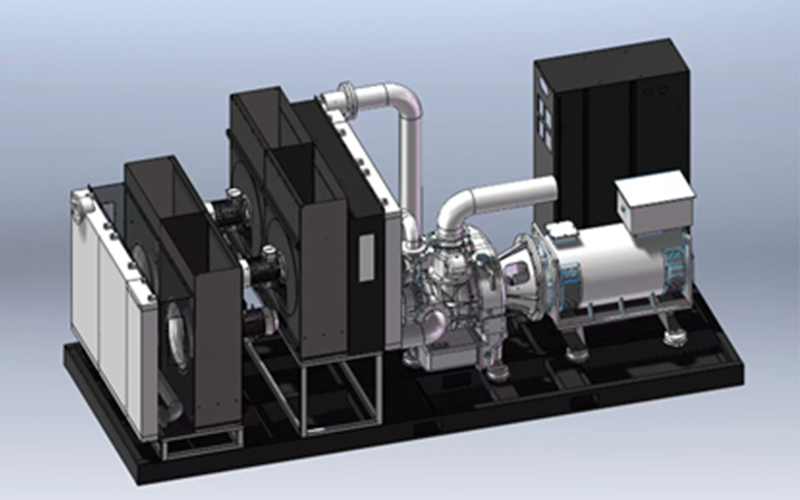

Oil-Free Energy-Saving Solutions The oil-free series from KOTECH includes oil-free scroll compressors (3.7-7.5kW), single screw water-lubricated compressors (7.5-55kW), oil-free screw blowers (37-75kW), dry oil-free compressors (55-315kW), and oil-free centrifugal compressors (160-2000kW). These products are certified to ISO 8573 Class 0 oil-free standards (certified by TÜV Rheinland), ISO quality management certification, and CE certification.

The KOTECH dry oil-free compressor, with its oil-free, pure, environmentally friendly, and reliable compressed air power, is widely used in the chemical industry, food processing, medical equipment, air separation, experimental technology, new energy, aerospace, and other fields requiring oil-free compressed air energy, providing an ideal air source for production.

The KOTECH dry oil-free compressor meets the requirements of high temperature, corrosion resistance, and chemical process-compatible compressed air in chemical process production, improving production efficiency and product quality in the chemical industry. In addition to the chemical industry, KOTECH oil-free compressors have been widely used in food biotechnology, pharmaceuticals, precision electronics, new energy, and other industries, providing customers with stable and reliable oil-free production power.